Many modern heating systems are controlled automatically and require a constant supply of electricity to operate correctly. If there are regular power outages, experts recommend purchasing a backup generator. When the absence of electricity is rare and does not last long, it is enough to install a progressive inverter for the heating boiler.

It converts the direct current coming from the battery into alternating current and allows the heating equipment to fully function for a certain time even in the absence of electricity. Let's take a closer look at the main characteristics of the device.

An inverter is primarily a DC to AC converter. In parallel, it changes the transmission amplitude and generates an output signal of a suitable frequency. The device itself cannot charge the battery and monitor its current capacity.

Many modern manufacturers equip their products with accompanying elements, additional chargers and a control control unit. Such models are already classified as uninterruptible power supplies (UPS) and have the ability to solve a wider range of problems.

Manufacturers provide a great guarantee for the uninterrupted operation of inverter equipment for boilers - from 10 to 12 years with 600-620 active cycles and battery discharge at 80-83%

Integrated into the heating system, they monitor the presence of current in the network and, in the event of a sudden emergency shutdown of the electrics, maintain full operation of the equipment for some time.

In this way, preventing potential freezing of water in pipes and radiators (in winter), breakdown of individual parts of the system and other unpleasant problems.

An inverter equipped with an additional battery allows heating equipment to operate for a long time and efficiently even in the absence of a centralized electricity supply for a long time

Simple, low-cost products perform only one direct function - providing the boiler with energy to operate for a certain amount of time. Complex progressive modules have expanded potential.

In addition to their main mission, they act as stabilizers and equalize the voltage in the system, thus protecting equipment from excess load and failure.

Complete set of inverter energy sources

In the modern market of household related equipment, inverters are presented in several versions. Some brands produce extremely simple units that work only as voltage converters.

The rechargeable battery is not initially included in the package of such modules, but its connection is allowed by the design, and the user can purchase this element separately in the future.

You need to purchase inverter equipment only from the regional official representative office of the manufacturer. There, in addition to the product, the buyer will be given a warranty card for service and, in case of problems identified in the first working days, the product will be replaced with a working one

Some types of inverters have a built-in battery of a certain, usually small capacity, but increasing its volume using external additional batteries is not possible.

Devices of this type keep the heating equipment operating for a short time and mostly serve to enable the owner to correctly disconnect the system from the power supply in an emergency.

A basic battery is built into universal units. Expanding the capacity of the device is carried out by adding external batteries. In this way, the operating time of the device is increased from several hours to several days.

Product design features

The inverter has optimal dimensions and is shaped like a parallelepiped. Placed on the floor in close proximity to the boiler or mounted on the wall (if provided for by the design features of the purchased model).

The working battery transmits 12 V direct current. The inverter absorbs it and converts it into alternating current with a traditional voltage of 220 volts, and also monitors the state of charge of the battery itself

In advanced models, a control unit with a boiler switching system and a basic battery are located inside the housing. The first node monitors the availability of energy and promptly switches the equipment to autonomous operation if interruptions in the supply of resources occur in the central network.

The second unit (battery) provides power to all electronic elements of the boiler for the entire period of power outage or until the charge runs out.

How are devices classified?

Almost all inverter devices are components of a UPS (uninterruptible power supply) and perform the same function - convert direct current from the battery into alternating current.

In the event of an unexpected power outage, the backup power supply system is activated, and the heating equipment instantly switches to autonomous operation. This allows you to maintain the full functioning of the heating over a certain period of time - from several hours to several days.

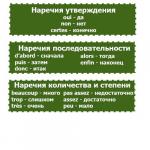

Based on the principle of operation, the devices are divided into three types:

- Off-line (backup);

- Line-interactive (line-interactive);

- On-line (double conversion).

Each type of device has its own specific characteristics and capabilities that allow it to solve diverse problems. After thoroughly studying the parameters of all three devices, choosing the best option for yourself will not be difficult.

Operating principle of Off-line units

The off-line model has a simple design and is considered a backup model. When the electrical network operates in standard mode and demonstrates stability, and the voltage does not “jump” between extreme values, the device “sleeps” and does not participate in the operation of the household heating system.

If the current level drops to 175 V, the unit switches to recharge from the battery. As soon as the situation is restored, the inverter UPS reconnects the heating equipment back to the main network.

The off-line device is ideal for working in conjunction with a gas heating boiler, but only if there are no problems with voltage stabilization in the central power grid

Each transition from the main power source to an autonomous one and back lasts no more than 10-15 seconds and does not in any way affect the functionality of the heating equipment.

The operating range of most off-line converters lies in the range of 170-270 V.

Progressive inverter converters are usually equipped with informational liquid crystal displays and current regulators. They do not have an active cooling system. Due to this, the work process is absolutely silent and does not disturb residents with annoying sounds.

With a constantly “jumping” voltage, switching from the main system to the autonomous system occurs too often and leads to rapid wear of the batteries and the device itself. Stabilizers are not included in the device, so when connected, both at the input and output, the mains voltage does not change.

Depending on the manufacturer and model, backup appliances can effectively handle electrical equipment ranging from 300 to 3,500 watts. Some products provide cyclic operation and the ability to prevent communication parts of the heating system from freezing for a day or more.

How do Line-interactive modules behave?

The Line-interactive device is a switching type device and is considered the best option for universal equipment. Structurally, the product consists of an off-line source, a converter, a switching relay and a low-frequency stabilizer device.

In the standard operating mode of the unit, the heating equipment consumes the resource of the central energy main. The output voltage is controlled by a stabilizer and special filters (for some models), smoothing out noise and neutralizing interference from the network to which the boiler itself is connected.

A gas boiler connected to a line-interactive converter equipped with an additional external battery can operate from 8 to 10 hours (depending on battery capacity)

Line-interactive type units supply electrical appliances with useful energy for a very short period of time (no more than 20 minutes).

To provide heating boilers with a resource, they use not ordinary liners, but improved products with an expansion function, which provide for the connection of an additional external battery. Such devices can keep the boiler operating for a longer time (up to 10 hours depending on the manufacturer).

The line-interactive converter brings the battery into operation extremely quickly (approximately 2-4 seconds). The output flow of the device can be pulsed or sinusoidal. Experts recommend installing the second option on heating boilers

The built-in current stabilizer allows the equipment to operate correctly without switching to a battery over an extended voltage range. The device provides backup power from the battery and equalizes the mains voltage. The disadvantages of the products include the inability to correct the flow frequency of the current and minimal smoothing of the sinusoid (no more than 20%).

Features of on-line devices

Online devices operate in constant mode.

The conventional diagram for connecting heating equipment in this embodiment is constructed in the following sequence:

- central electrical network;

- inverter uninterruptible power supply;

- boiler.

The principle of operation of the device comes down to repeated transformation of the general parameters of the electrical network. At the first stage, when entering the inverter, the alternating voltage is converted into a stable equivalent with an indicator of 12 V.

Then the reverse maneuver occurs and at the output of the inverter apparatus the voltage turns into alternating voltage with a value of 220 V.

In online systems, the battery performs a buffer function and is constantly being recharged. In parallel, the output converter is activated inside the battery and forms an alternating voltage from a direct voltage with indicators of 220 V 50 Hz, no longer depending in any way on the voltage generated at the input

The main advantage of a system of this type is the provision of high-quality voltage to the power supply unit of the heating boiler. There are only two disadvantages: the high cost of conversion equipment and the low level of performance.

Advantages and disadvantages of equipment

The inverter is convenient because it is not tied to a specific type of DC voltage source. The unit can be powered using a regular car battery, a generator set with a simple signal rectification principle, or from UPS batteries.

If the module does not have a built-in charger, the owners will have to personally control the capacity level and the degree of discharge of the device.

Among the main advantages of the device:

- a wide range of models and the ability to select a product with an almost ideal output sinusoid;

- correct operation with all sources of rated voltage and direct current;

- reasonable cost compared to other similar units of similar power;

- no restrictions on increasing battery capacity and duration of autonomous operation.

Disadvantages include criteria such as:

- lack of control over the battery charging/discharging level;

- the response threshold setting is not subject to additional correction;

- the need to arrange an external communication circuit for automatic activation in the event of a power outage in a residential area;

- high cost of “sophisticated” modules with a wide range of capabilities.

The final choice of a suitable device is strictly individual. It all depends on how much the voltage “jumps” in the network, how often consumers are cut off from the supply of resources by the central electrical system, and how long they have to sit without power.

Basic rules for choosing a module

When planning to purchase an inverter for a boiler, you need to pay close attention to such parameters as:

- indicator of input voltage and current;

- output voltage level;

- degree of distortion of the output voltage sinusoid;

- actual conversion factor;

- total power output.

For households, inverter units 12-220 are mainly used. These units convert 12V DC battery voltage into 220V sine wave voltage with minimal distortion.

The sine wave of the inverter output voltage should not exceed 3%. These indicators mean that the signal shape is as close as possible to a sine wave with minor deviations towards a sharp decline or cut off peaks

You can also acquire a more powerful combination of units (24-220 converter and 24 V battery), but you need to find out exactly what maximum input current the inverter is designed for.

Only after receiving this information should you start purchasing.

Inverters offered on the domestic market are initially designed for low quality electrical networks. The units have all the functions of protection against energy surges and an option that allows the user to set upper and lower voltage limits down to volts

The controller and control unit of popular gas boilers usually consume power of about 150-200 W. Responsible for the proper circulation of the heating fluid in the system, it takes another 125-150 W. To determine the required power of the inverter, these data must be added and multiplied by 2.5 to take into account the volume of starting current at the time of startup.

The finished numbers must be multiplied by 1.2 again to take into account some power reserve. Remember or write down the received data. When purchasing an inverter, make sure that the base power declared by the manufacturer certainly exceeds the calculated values.

List of popular models and manufacturers

There are many domestic and foreign companies, firms and organizations operating in the electrical engineering market segment. Some of them produce products under license, others develop their own technologies and offer customers unique, innovative and competitive products at a very reasonable price.

Device of the company ETK "Energia"

Inverter Energy PN-500 is an inexpensive, practical device that provides uninterrupted power supply for modern low-power boilers. Manufactured at the production facilities of ETK Energia, one of the leaders in the domestic electrical market.

ETK Energia inverters fully comply with all GOST standards and requirements for household electrical equipment. The environmental safety and quality of products are confirmed by international certification certificates issued to the company.

Connecting one basic battery to the device ensures full autonomous operation of the fuel boiler for 6-7 hours. If you connect a second battery, the operating time will double.

The unit produces a pure sine wave at the output, which helps preserve the expensive electronic “filling” of modern heating boilers. When the operation of the central electrical system returns to normal, the inverter automatically switches to voltage stabilization mode and protects the boiler from sudden power surges.

Device "Elim-Ukraine"

The Elim-Ukraine company has been operating in the electrical equipment market for more than 10 years and is respected by customers.

Devices produced under this brand have a switching power supply, eye-pleasing LED display and demonstrate an extremely high level of efficiency (up to 98%). Produces a pure sine wave signal without distortion or surge levels.

Inverters from Elim-Ukraine are also convenient because they work correctly with both gel and car batteries

Equipped with protection against overheating, general overload and deep battery discharge. One of the expansion options allows you to connect an additional battery of any capacity to the equipment to maintain autonomous operation of the heating system even in the absence of voltage in the central main networks for a day or more.

Unit Rucelf UPI-400-12-EL

The Rucelf UPI-400-12-EL device belongs to the category of linear-interactive energy sources. It has a built-in stabilizer, which, even if there is a minimum mains voltage, equalizes the current flow without using the battery. This makes it possible to economically use the battery life without overloading and extending their service life.

Important advantages of Rucelf UPI are completely silent operation and efficient provision of devices with the necessary power supply during a power outage

Reasonable cost is another characteristic feature of the products of the Russian company Rucelf.

Thanks to this, customers can create a full-fledged autonomous infrastructure to recharge heating systems during emergency power outages or power surges.

Conclusions and useful video on the topic

How to buy the right inverter and choose the optimal capacity battery for it. How to install equipment on the boiler and forget about electrical interruptions forever:

A detailed overview of the device, operating principles and functionality of the popular model of voltage inverter unit with a pure sine wave:

How does an inverter voltage converter that does not have a built-in battery inside the case behave:

Installing an inverter device on a heating boiler allows the heating system to function correctly during intense voltage surges and during a general blackout. The owners do not feel any inconvenience due to the lack of electricity and do not freeze if this unpleasant situation happens during the cold season.

In addition, the device protects communication elements from possible breakdowns caused by an unexpected blackout, and helps the equipment operate as long as possible and with maximum efficiency.

Already have experience using inverters for heating boilers? Please tell our readers which device you chose? What were you guided by? Are you satisfied with the device's performance? Leave your comments, share your experience, ask questions in the block below.

If an electric or gas boiler is used for a closed heating system in a personal home, then if there is an interruption in the supply of electrical energy, the heating of the premises will naturally be stopped. To avoid such an unpleasant phenomenon, a special device was invented - a voltage converter for a heating boiler, which converts the stable battery voltage into a sinusoidal voltage of 220 volts with a frequency of 50 Hz.

Specifications of voltage converters for gas and electric boilers

The voltage converter is part of an uninterruptible power supply (UPS) for volatile systems. IBNs duplicate electrical power, which significantly improves the reliability of heating equipment. These emergency power supply devices turn on quickly when the voltage level drops or when there is no voltage at all.

In heating systems of private homes, the following uninterruptible power supply options are used:

- backup IBNs, which are turned on only when the 220 V network voltage disappears or decreases below a specific threshold;

- linear-interactive devices contain an electrical voltage stabilizer for good and safe operation of the boiler’s electronic equipment;

- Double change systems operate regularly online.

When selecting an IBN, it should be taken into account that the voltage converter for a gas water heater must provide power sufficient for the good functioning of all consumers of electrical energy - a circulation pump, an automatic unit. In fact, this power is usually no more than 300 W, taking into account the required margin.

For electric boilers of various types, when selecting an IBN, it is necessary to add the power consumed by the boiler to the power used by the automation unit and circular pumps.

Inverter electric heating boilers

If we strictly approach the term - inverter heating boiler, then this name corresponds to a device whose power is supplied through a double-change voltage converter. The 220 volt network voltage is rectified and supplied to a voltage converter, which converts stable voltage into high frequency voltage in the range of 15 - 40 kHz to power the inductor (winding) of an electric induction boiler.

Several types of induction boilers are known:

- electromechanical heating boilers SAV;

- electromechanical vortex boilers VIN.

SAV electric boilers are connected specifically to the electrical network, single-phase or three-phase, depending on the power and connection diagram. If a cascade connection is used to increase power, then each device is connected to an individual phase.

Vortex electromechanical boilers of the VIN type were developed as inverter heating boilers with high-frequency voltage supply to the inductor.

The use of high frequency made it possible to reduce the dimensions of the boiler, the number of turns of the inductor winding and reduce its weight.

Most manufacturers recommend VIN vortex boilers, which, for some reason, require a power supply of 220 v 50 Hz, i.e. such a home heating boiler turns out to be a modernized SAV type boiler. It cannot be called an inverter vortex device of the VIN type, since the very principle - the use of high-frequency voltage - has been lost. There is a lot of confusion on the Internet regarding the use of terms and concepts. It even goes as far as outright deception. For example, an induction electric boiler A006 is offered. Let's look at its technical data:

- total power of TENOV – 6 kW;

- step power adjustment – 3/6.

Only such parameters clearly determine that the boiler belongs to the heating element heating devices.

Despite the fact that induction equipment is one of the most economical, safe and reliable, its widespread adoption is hampered by the price of electrical energy. The use of IBN, which includes voltage converters for heating, is fully justified in conditions of an unstable network, because increase the reliability of the circuit and provide operation without interruptions. The term inverter heat supply can be used exclusively for vortex induction boilers of the VIN type, the inductor of which does not stop operating from the high-frequency voltage generated by the voltage converter.

Heating system for a private home Protection against power outages

Inverter home heating, what and how does not stop working

1. Design of inverter heating boiler

2. Pros and cons of inverter heating 3. Installing an inverter boiler with your own hands 4. Independent power sources

The heating system is considered one of the most important components of every home, since it is impossible to talk about comfort in an unheated house. Heat supply is considered very important in cold climates. The choice of heating system depends on most indicators, but the key ones are efficiency and economy. Very often, heat supply is used for six months, and in certain regions - all year.

Compared to most types of heating systems, inverter heating boilers stand out as a bright spot, which stand out with an unlimited number of indicators. Inverter heating belongs to the category of devices that use electrical energy to heat a house. Basically, the majority of electric heating structures consume a very large amount of energy, so manufacturers are putting every effort into increasing the efficiency of these systems. This publication will discuss the working principle and specifics of inverter heating. In an inverter boiler, the heating medium is heated by converting electricity into heat; ultimately, the batteries are heated from the network. The boiler consists of two circuits: magnetic and heat exchange. The magnetic circuit is considered to be a coil of conductor attached to a dielectric. This circuit creates an electromagnetic field that acts on a metal core installed in the heat exchange circuit. The core itself transfers the resulting heat energy to the thermal carrier. Heating voltage converters are one of the most promising types of heating devices that can be used both for heating personal homes and as a heater for industrial buildings.

Pros and cons of inverter heating

The list of differences is quite impressive:

- The design of inverter boilers has no moving parts or mechanisms, making such devices more resistant to wear. Likewise, the working life of inverter boilers is much longer than similar devices of a different type and in most cases is at least 10 years.

- Inverter boilers have a fairly conventional design, and if necessary, you can assemble it yourself.

- The coolant in inverter boilers heats up much faster than in any other heating system. The reason is very simple: inverter-type devices do not have an ordinary heat exchanger, so all the thermal energy is used to heat the coolant.

- Almost every inverter boiler is capable of working with any type of coolant, since the working parts of the boiler do not come into direct contact with the coolant. The coolant can only influence the characteristics and performance of the heating system, but the boiler will operate normally.

- Inverter boilers are expensive: in comparison with ordinary home appliances, an inverter boiler will cost at least several times more.

- Home inverter boilers are heavy, but the size of such devices makes up for this disadvantage. Moreover, the successful form allows such a structure to be placed virtually anywhere.

- Boiler adjustment is carried out using complex electronic systems that will ensure continuous operation and monitoring of boiler performance. Likewise, despite the ease of assembling the boiler itself, to create the control components yourself, you will have to learn electronics. Installation of electronic systems is considered mandatory, otherwise the equipment may be damaged and break down.

- Inverter radiators do not make noise and are fireproof devices: no fuel is used during operation, which could result in an ignition, and there are no moving parts.

- Such systems are environmentally friendly: since no fuel is used, there are no emissions into the environment that surrounds us, because there are no gaseous, liquid or solid substances.

In an inverter boiler, the coolant is heated by converting electrical energy into thermal energy; as a result, the batteries are heated by electricity. The boiler consists of two circuits: magnetic and heat exchange. The magnetic circuit is a coil of conductor attached to a dielectric. An electromagnetic field is created in this circuit, which acts on a metal core installed in the heat exchange circuit. It is the core that transfers the received thermal energy to the coolant. Heating inverters are considered one of the most promising types of heating devices, which can be used both for heating private houses and as a heater for industrial buildings.

Advantages and disadvantages of inverter heating

Inverters, in a broad sense, are devices that convert direct current into alternating current, and their operating principle is based on the phenomenon of electromagnetic induction. How does inverter heating differ from other types of heating systems?

The list of differences is quite impressive:

- The design of inverter boilers has no moving parts or mechanisms, so the wear resistance of such devices is higher. Thus, the service life of inverter boilers is significantly higher than similar devices of other types and is usually at least 10 years.

- Inverter boilers have a fairly simple design, and if necessary, you can assemble it yourself.

- The coolant in inverter boilers heats up much faster than in any other heating system. The reason is simple: inverter devices do not have the usual heat exchanger, so all the thermal energy is used to heat the coolant.

- Almost every inverter boiler can work with any type of coolant, since the working elements of the boiler do not come into direct contact with the coolant. The coolant can only affect the characteristics and performance of the heating system, but the boiler will operate normally.

- Inverter boilers are quite expensive: if compared with conventional household appliances, an inverter boiler will cost at least 2-3 times more.

- Household inverter boilers are heavy, but the dimensions of such devices compensate for this disadvantage. In addition, the successful shape allows you to place such a structure almost anywhere.

- The boiler is adjusted using complex electronic systems that will ensure continuous operation and control of the boiler parameters. Thus, despite the simplicity of assembling the boiler itself, to independently create control elements you will have to study electronics. Installation of electronic systems is mandatory, otherwise the equipment may be damaged and fail.

- Inverter heating devices do not create noise and are fire-safe devices: no fuel is used during operation, which can cause ignition, and there are no moving elements.

- Such systems are environmentally friendly: since no fuel is used, there are no emissions into the environment, because there are no combustion products.

Radiators for water heating systems

Different types of devices differ not only in price, but also in efficiency and reliability. When making a comparison of heating radiators for a water circuit, the owner should study the possibility of installing them in various types of heating systems.

The most popular types of radiators in the modern heating equipment market are:

- cast iron;

- steel;

- bimetallic;

- aluminum.

Cast iron batteries

Depending on the metal used to produce the battery, the thermal power of the heating radiators varies, which is indicated by the manufacturer in the technical documentation of the device. Cast iron radiators are considered the most advantageous in this regard - they heat up for a long time and cool down slowly, so they can ensure smooth heating of the house even when the boiler is turned off. According to the circuit diagram, the supply to a cast iron heating radiator can be either single-pipe or double-pipe.

Alternative options

In recent years, heating equipment manufacturers have achieved new heights and introduced innovative radiators to the market that have caused unprecedented excitement. Therefore, asking a question at a hardware store: what types of heating radiators are there? - the buyer may receive a rather open-ended answer. Alternative heating devices are presented in various models and can also be considered by owners as basic elements of a home heating system.

The following models suit you

Selection by parameters

Description of cast iron vertical batteries

Vertical heating radiators are also called tall, and it is not possible to install them in the traditional way, because the window opening simply will not accommodate such a device. Devices differ according to the material they are made of. Among others, you can find cast iron radiators on sale, which have many advantages, namely:

- high heat transfer coefficient;

- no restrictions on coolant acidity;

- ability to withstand high pressure in the system;

- high corrosion resistance;

- average cost.

However, these devices are heavy and thermally inert. Their installation requires sufficiently strong fastenings and appropriate strapping. It is not possible to install thermostats on this equipment.

Disadvantages of aluminum appliances

However, such devices also have disadvantages, they include high cost, a limitation on the pH of the coolant, which must be equal to or greater than 7, and the need to use an automatic relief valve. One cannot fail to highlight one more feature, which is the limitation of the operating pressure in the system. This parameter should not be more than 10 atmospheres.

Reviews of tubular vertical radiators

Such batteries are the most progressive today, which is why they are so good for realizing design ideas. According to buyers, similar devices of any shape can be found on sale, but they will have less impressive heat transfer.

Consumers emphasize that such heating devices have leak-prone areas that are located in the welding areas. The devices can be used for individual heating systems. And owners of private houses note that they try to choose devices whose interior is coated with polymer paint, as this reduces the risk of corrosion.

Reviews of vertical radiators in terms of connection type

When choosing vertical batteries, you should pay attention to their classification. Devices are divided into: smooth, ribbed, sectional, tubular and linear. However, it is also important to consider the type of connection, which can be bottom, side or diagonal. According to buyers, the first type of radiator is the most expensive, but most common. With a bottom type of connection, installing a vertical radiator will be quite simple, but the pipes are installed inside the wall; they can also be placed in a decorative box.

Home craftsmen note that the side connection cannot be called effective, because the coolant in this case can remain inside the radiator even during the warm period, which negatively affects the quality of the device. When choosing vertical radiators, photos of which are presented in the article, you can also pay attention to those that require a diagonal connection. According to consumers, it is the most efficient; the entrance will be located at the top and the exit at the bottom. The dimensions of the devices do not have limited standards, and the height can reach 6 m with a width of up to 3 m. If you want to improve the efficiency of the heating system, then, according to buyers, it is best to choose two- or three-layer structures.

Positive reviews about vertical heating devices

Vertical high radiators are gaining popularity quite rapidly, this is due to many factors. Among them, consumers highlight:

- a huge selection of design and color solutions;

- relative compactness;

- wide range of fastenings;

- easy installation;

- large heat transfer area.

You can purchase such devices not only in the store, but also from private manufacturers who make custom-made devices in the form of mirror panels, tubular figure eights and other intricate elements. Buyers note that this fact is the most significant criterion when choosing tall radiators.

If you want to decorate the premises of your apartment, which has a rather limited area, but want to resort to modern design solutions, then vertical heating devices will be the best choice for you, because they will not take up space at the bottom of the room, and for panoramic glazing they will be the only right solution . If desired, vertical heating radiators in Tver can be purchased for 8,700 rubles. In this case we are talking about a tubular radiator. But such an affordable price is not the only advantage. Consumers also consider the ability to choose different wall materials for installing batteries to be a plus. The radiator can be mounted on brick, cement, concrete, etc. Installation will be quite easy, and additional skills, tools and knowledge will not be required, which will save money.

Types and design of electric heaters

We immediately warn you that we are not talking about traditional heating devices of infrared or convector type. We are considering heaters made in the form of ordinary mounted heating radiators (shown in the photo), but powered from the house electrical network.

At the moment, online stores offer the following types of electric batteries:

- sectional heaters of the “dry” type;

- ceramic heating panels;

- vacuum wall radiators using electricity;

- universal vacuum batteries capable of operating from electricity or the classic coolant - water.

To make positive or negative conclusions about the listed products, you need to understand their structure and principle of operation. Plus study the reviews of users who managed to buy and test the operation of electric batteries for heating a private home. Let's look at each product separately.

Liquid-free sectional units

In appearance, the product resembles a sectional radiator made of aluminum alloy, attached to the wall and designed to work in a water heating system. Only on the sides there are decorative plastic panels, one of which has a built-in control panel with a display.

The inside of the device looks like this:

- battery sections are cast from an aluminum-silicon alloy (silumin) and equipped with heat exchange fins;

- each section has a built-in tubular heater (TEN) with a power of up to 200 W;

- the elements are twisted together, and the heating elements are connected to the power line in a parallel circuit;

- heating is controlled by a thermostat connected to an electronic unit.

Note. The user sets the required room temperature on the display, and the thermostat maintains it automatically. It is possible to switch to an economical operating mode when half of the heating elements in the electric battery are inactive.

The principle of operation is extremely simple: the device is connected to the network, heating elements heat the finned sections that transfer heat to the room. Since the maximum surface temperature is 80 °C, heat transfer occurs in two ways - infrared radiation and convection (direct heating of the air). The required power is obtained by the number of sections.

Each section is equipped with its own heater, there is no coolant

Now comes the fun part. The price of an electric radiator with a power of 0.8 kW from 4 sections of a standard size of 500 mm, offered by the Russian company Effect Energo, is 210 USD. e. (12.5 thousand rubles as of autumn 2017). For comparison: a convector from the famous European brand Nobo (Nobo) model Oslo NTE4S 10 with a heat output of 1 kW costs 9,200 rubles. or 155 USD e.

Reference. The price of 1 section of an aluminum Italian Global radiator, similar in appearance to an electric battery, is 9 USD. e.

Ceramic panels

These products with a pleasant external design are a “layer cake” of several elements shown in the diagram:

- The front part is a 10-20 mm thick ceramic plate. Usually decorated with a cute design or photo print.

- A heating element is installed behind the stove - a chromium-nickel spiral laid in a snake pattern (another option is a carbon heater).

- At the back of the heater there is a metal sheet, profiled as an accordion.

- The last part is the protective casing.

Diagram of the internal structure of a ceramic heating panel

There are no revolutionary solutions in the operation of a ceramic electrical panel, although the device is quite successful. The spiral heats the front plate and the rear steel sheet to 80-85 ° C, causing the first to radiate infrared heat, and the second heats the air passing along the bends of the profile due to convective circulation. There is a control panel and thermostat.

The power of electric radiators depends on the size. A 0.6 x 0.6 m panel consumes (respectively, releases into the room) about 350 W, depending on the manufacturer. So that you have an idea about ceramic electric heaters, we suggest watching a short video without taking seriously the words of the speaker about the wonderful properties of the device.

Another interesting note. The price of a product 1200 x 600 mm at 0.99 kW, comparable in power to the Nobo convector mentioned above, is 15.9 thousand rubles. or almost 270 USD e.

Looking for real benefits of heaters

Advertising of the listed varieties of electric radiators focuses on the main parameter that attracts buyers - efficiency from 20 to 70%. Product descriptions develop scientific theories designed to confirm the stated savings in any way. Other tricks are also used: instead of thermal power, the heating area is indicated in the characteristics.

We will dispel the myth of extreme efficiency with a simple explanation. No matter how high-tech the design of electric batteries is, it only serves as a transmission link. Thermal energy is produced by the heating element (or brought by water from the boiler), and the remaining elements of the heater are needed to transfer it to the premises of the country house.

In this vacuum battery, the working fluid (secondary coolant) is heated by water from the boiler

Hence the conclusion: if the power consumption of the heating element is 1 kW, then you will receive 980 W of pure heat (efficiency = 98%) regardless of the design of the heating device. The more bells and whistles are made around the heating element, the higher the price of the final product. The efficiency of these “innovations” in terms of heat transfer tends to zero.

Now let’s take a look at the rest of the advantages declared by sellers one by one and immediately comment on them:

Note. It is customary to protect hot surfaces from children with decorative covers, but the latter block the path of radiant heat, converting it into convective heat (they heat up themselves and interact with the air).

Liquid mini-boilers are generally overgrown with mysticism. There is no pressure and little coolant in them, so the heat transfer is supposedly higher. Another example: during the process of liquid condensation, a huge amount of energy is released, which is used for heating. True, it is not said where this volume of heat came from, because the power of the heating element is only 1 kW. Probably from space.

2180 Arbonia vertical radiators with side connections

The Arbonia 2180 radiator stands out from its peers not only with its minimalist design, but also with its wide color palette. This tall and thin radiator is installed vertically, takes up minimal space in the room and is the best option for decorating the interior of a modern apartment. The Arbonia 2180 vertical radiator is an excellent replacement for traditional batteries, which also serves as a very attractive design element.

The Arbonia 2180 radiator, an excellent model of a vertical heating device, looks ideal in RAL 7016 (Anthracite grey), this shade can be called very original and interesting.

SIDE CONNECTION 3/4.

The Arbonia 2180 radiator model with side connections in Anthracite color (SF-3 Anthrazit metallic) is a thin, tall radiator with the smallest depth (65mm) painted in a dark graphite color, which eliminates glare on the surface when exposed to rays of the sun or light. The height of the device is 1800 mm (180 cm).

2180 N69 tvv vertical radiators Arbonia with bottom connection

Vertical radiator Arbonia 2180 N69 tvv with bottom liner is a thin, tall radiator with the smallest depth (65mm). The height of the device is 1800 mm (180 cm). Heating radiators with bottom connections Arbonia 2180 N69 tvv have become especially popular and are used in houses where pipes directly from the radiator go to the floor, which frees up space and improves the appearance of the room.

Vertical radiators Arbonia 3180 with bottom supply N69 TVV and N89 TVV

Arbonia 3180 - also features a 3-pipe radiator model with a height of 180 cm and a depth of 10.5 cm. The standard radiator is painted white (RAL 9016). The vertical heating radiator 3180, with its high heat output, takes up little space and has an interesting design. Heating radiators with bottom supply, for example the Arbonia 3180 N69 tvv series, have become especially popular. This type of connection is known for its ability to hide supply pipes in visible places.

Vertical (high) heating radiators Arbonia. Comfort and style.

Arbonia vertical radiators differ from their usual counterparts in their interesting design and wide palette of colors. From the name it is clear that such radiators are located vertically, and thanks to this they take up minimal space in the house, and are successfully integrated into the decorative elements of the interior decoration of the apartment. Narrow and tall arbonium batteries, taking up little space, are excellent for heating apartments, private houses and cottages.

In modern apartment interiors, owners are increasingly concerned not only with comfort, but also with the harmony of design. When choosing the style of a room, we carefully select interior items that would decorate and not spoil the overall picture. Therefore, conventional (radiator) heating systems, which do not fit into the interior in any way, are today being successfully replaced by tall radiators, which, fortunately, are no longer uncommon on the domestic market. You can select and purchase vertical radiators in our online store.

What are the advantages of such Arbonia radiators?

1. Having a fairly compact size, such a radiator can be easily placed in any part of the room.

2. Tubular high radiator Arbonia is a fashionable and aesthetically pleasing new product. Such a battery does not need to be hidden behind a curtain.

3. The connection to the central or autonomous heating system for these radiators is made traditionally - from the side, through radiator plugs, or from below.

4. Various shapes of vertical radiators. They can be made tubular in the form of sections, linear, ribbed or smooth.

Our catalog presents a wide range of tall radiators for every taste.

Tall (batteries) are a worthy replacement for cast iron batteries and an effective design element.

You can buy the above radiators from the Arbonia.net online store at an affordable price. Arbonia tubular radiators: prices, descriptions, photos and characteristics, as well as customer reviews.

Free calculation and selection of heating radiators, express delivery in Moscow and the Moscow region and the official manufacturer’s warranty for the entire range of products, you can find all this on our website.

According to the material of manufacture

Vertical heating devices have quite large dimensions and weight, so manufacturers try not to increase the load on the walls due to sections made of cast iron.

In addition, the complexity of processing this metal does not allow it to be given decorative shapes. These factors rule out cast iron as a material for tall batteries.

It is advisable to plan a heating system from vertical radiators at the stage of building a house or major renovation of an apartment, so that communications can be hidden behind the walls

The main types of vertical radiators, depending on the material of manufacture, are:

- bimetallic;

- aluminum;

- steel.

Modern bimetallic heating sections are good because their tubes and system of internal channels are made of steel, and the heat-emitting fins are made of aluminum. This allows you to combine the strength and wear resistance of one metal and the good heat-conducting properties of another in one device.

Bimetallic vertical batteries are highly reliable because they contain a minimum of threaded connecting elements that can leak

In addition, the ease of machining aluminum allows you to vary the appearance and shape of radiators within a wide range. This metal can be painted well without losing its thermal conductivity properties, which makes it possible to integrate products made from it into an interior made in any palette. The only disadvantage of bimetallic products is their increased cost.

Steel heating sections are characterized by increased structural strength, but among all vertical radiators they have the worst heat transfer. Steel does not lend itself well to precise machining, so the appearance of batteries made from this material is often not distinguished by sophistication. In addition, steel structures are susceptible to corrosion, even if they are coated with a special coating.

Tubular steel radiators can have from two to six channels per section, so the battery can be made narrow but deep

Steel sections are often manufactured in panel construction, allowing pipes and ducts to be hidden behind external metal plates. The advantage of such radiators is their price, which is lower than that of products made from other materials.

Aluminum heating sections have the best thermal conductivity among other materials. They heat up quickly, but don't hold heat for long. Aluminum is a plastic material, so batteries made from it are distinguished by their exquisite design shapes.

Aluminum vertical radiators are the lightest, so they can even be mounted on interior partitions without the risk of deformation.

Due to the ease of manufacture, the cost of aluminum sections is lower than bimetallic ones, but their maximum operating pressure is also lower. Weak strength does not allow the use of such radiators in multi-storey buildings and in centralized heating systems.

The material of the batteries can influence their choice only at high operating pressure, so most often products are purchased based on their appearance and cost.

According to external design

The larger the heat-reflecting surface area of the heating metal elements, the higher their efficiency. Therefore, the shape of the battery design largely determines its energy performance. All radiators according to their external design are divided into:

- sectional;

- tubular;

- panel.

Tubular vertical batteries consist of elongated pipe sections connected at the top and bottom by collectors. To give an elegant look, individual radiator elements are often curved. This device provides maximum heat transfer, but to preserve it, it is necessary to regularly wash the batteries on all sides.

The advantage of tubular structures is the possibility of arbitrary bending of the channels, which allows you to create elegant shapes without sacrificing reliability and price

Such radiators are usually made of steel, and individual pipes are connected to the collector by welding.

Sectional batteries consist of several parts with a flat front surface. They are characterized by the following features:

- are predominantly bimetallic or aluminum, which compensates for the reduction in working area when comparing their performance with tubular models;

- fit aesthetically into the interior;

- are more expensive than other types of batteries;

- give off heat primarily by convection;

- are collapsible, which allows you to assemble an arbitrary number of sections in one battery.

Caring for sectional radiators is simple and does not require much time.

The width of sectional vertical radiators can be arbitrarily changed by adding new sections. With the help of a special key, every owner can do this

Panel batteries have a non-separable design, and their front panel is often represented by a single sheet of metal or glass. Particularly popular are models with mirrored front surfaces, which are independent interior items. They expand the space of the room, adding light and internal warmth.

Panel radiators have a minimal contact area with air, but have a refined shape and are easy to clean the surface

If there is an autonomous heating system, the energy efficiency of vertical radiators of various designs is not of fundamental importance, because the heat produced by the boiler will in any case remain indoors.

By type of heat source

Most vertical heating devices use water as a coolant, which is heated by a gas boiler. But there are batteries that use electrical energy for heating. Their internal structure is similar to that of water batteries, only a special oil plays the role of coolant.

Electric models pose a certain danger to children. In addition, they are quite powerful, so if installed poorly, the wiring may catch fire.

The use of electric vertical radiators is economically expensive, so they are used primarily for short-term auxiliary heating of premises. Such equipment has built-in thermoregulation mechanisms, which allows it to be used only when the temperature drops below a set level.

Radiators built into the floor

The models of heating equipment discussed above provide for wall mounting. However, some homeowners prefer to buy heating radiators built into the floor, thanks to the unique design of which they can inexpensively heat an apartment, office or country house.

The peculiarity of installing radiators allows you not to spoil the interior of the room.

At the same time, the performance of the devices is also excellent - they are productive, energy efficient and affordable. The convector principle of operation of radiators built into the floor allows for uniform heating of the air in a room of any size, the main thing is to correctly select the power of the heating equipment.

By studying the features of various types of traditional and alternative radiators and discussing with contractors the feasibility of installing them in the heating system circuit, the owner will be able to achieve high-quality heating of the house with minimal energy costs.

spetsotoplenie.ru

Inverter heating batteries are “not afraid” of power outages

Modern housing is extremely vulnerable to interruptions in centralized supplies of electricity, cold water and gas. This dependence is most manifested in the operation of the home heating system, which depends on the supply of water as a coolant, and gas, as one of the options for heating the coolant. But the worst situation occurs when there is a power outage.

Without a constant power supply, the heating gas boiler, circulation pump and control automation will stop working. The house will be cold. If we take into account that the next time it is turned on, there will definitely be a power surge, to which the boiler automation will instantly react and block the operation of the boiler, then there is a need for human participation to turn on the heating system when the power supply is restored. But an elementary everyday situation, when no one is at home, or an elderly or sick person is at home, and there is no one to start the life support systems of the home, is fraught with serious consequences. Inverter heating batteries will come to the rescue.

Advantages of an inverter over a current generator when used in heating systems

There are plenty of advantages of the inverter both from the technical side and from the standpoint of routine maintenance and maintenance at home.

System startup, ready for work

- The generator is most often started manually. To do this, the owner needs to jump out in frosty weather into a special room with a generator placed there. Filling fuel (gasoline), switching switches and the starting procedure itself are not for older people, and children are generally prohibited from being allowed close to gasoline and the electrical panel. In addition, the generator will almost never start the first time while it is cold.

- The inverter will automatically start the battery power system within 10 milliseconds without anyone noticing.

No noise during operation

- Any gasoline or diesel generator produces a noise level of 80 dB, which is equivalent to the noise of a powerful truck. Not everyone can handle it. It is necessary to provide the generator room with reliable sound insulation.

- Inverter systems are absolutely silent.

No exhaust gases

- The exhaust gases of the generator must be removed from the premises using high gas exhaust pipes, which spoil the entire surrounding landscape with their appearance.

- Inverters do not emit exhaust gases.

Fire safety

- It is unsafe to store significant quantities of liquid fuel for a gas generator at home. It is unacceptable to trust children or elderly family members to refuel the generator. The room must be equipped with fire extinguishing equipment. There is no doubt that fire safety inspectors will be frequent visitors to such houses.

- The inverter does not require any fuel.

Peculiarities

It is logical that heating radiators are called vertical, the sections of which are located vertically. However, most batteries have a similar arrangement; devices with horizontally oriented sections are quite rare. In this regard, it is more correct to base the criterion on the shape of the rectangle formed by the batteries.

Thus, vertical batteries are those that form like a horizontally elongated rectangle. A distinctive feature of such systems is their orientation in height with a reduced width.

Thanks to this arrangement, it is possible to fit such batteries even into a small space, maintaining the required amount of thermal energy. The systems can be located almost from the floor to the flow, up to the height of a person. By spreading infrared thermal radiation (similar to solar heat) at the height of a person, they provide increased indoor comfort.

Vertical batteries have many design options and are distinguished by a variety of designs and colors. This allows you not only to fit them into any room, but also to make them an original interior detail. Such batteries, installed instead of the usual models placed under the windowsill, can not be hidden, but placed in any convenient place. In addition to practical, they perform a decorative function.

Finally, various product options can serve not only as a heater, but also as dryers and partitions. They even frame wall mirrors and also serve as various home decoration items.

When choosing vertical radiators, it is useful to know about their disadvantages. With this heating method, the principles of convection are violated, and therefore warm air accumulates under the ceiling, which is irrational. And when the batteries operate intensively, this warm air becomes the cause of an unfavorable microclimate. In addition, the likelihood of air pockets in the internal channels of vertical batteries increases.

Finally, installation of such a system is more labor-intensive. Even a slight vertical deviation will be noticeable and will disrupt the aesthetics. Difficulties arise with the installation of heating circuit pipes. In this case, you will have to abandon the most effective diagonal connection scheme. Otherwise, you will have to embed pipes into the walls, which is unaesthetic and unsafe in case of an accident.

The solution is to use a lower connection, which is not as effective and efficient as a diagonal one. In addition, vertical batteries require a reliable, powerful mounting system.

Tubular steel radiators

They are long pipes connected to each other at the top and bottom by collectors. The height of such products can reach 300 cm, so they are suitable for rooms with high ceilings. The tubes can have a round or rectangular (square) cross-section, be located at an angle, or have smooth bends. This allows you to give products unusual shapes and designs, as well as transform them into partitions and non-standard design elements. There are also corner designs that are ergonomic.

Tubular systems are considered more reliable than panel systems. First of all, their internal walls have an anti-corrosion coating, which increases the reliability and durability of tubular products. Unlike other steel structures, tubular ones are most resistant to hydraulic shocks.

They have a smooth outer surface from which dust and dirt can be easily removed. In addition, the system has no sharp corners, therefore it is considered the safest and is suitable for installation in children's rooms.

Aluminum products

They are distinguished by high performance properties. But they only appear when several criteria are taken into account, especially the quality of the coolant. In addition, they can only be installed in closed systems. Otherwise, oxygen is found in the coolant, which leads to metal corrosion.

The product is lightweight, neat in appearance, durable and affordable. Structures can be collapsible or non-dismountable.

The standard height is 185-200 cm. The products are characterized by high thermal efficiency, but they may overheat in the ribs area. Due to the chemical reactions of aluminum and the coolant, gas formation is possible, which can be avoided by equipping each section with an automatic gas vent. This complicates the process and increases installation costs.

What are the good and bad things about vertical batteries?

Vertical batteries are almost the same as standard ones. The difference is only a form. Among the advantages of vertical radiators it is worth noting the following:

- Having a lot of choice. On the heating appliance market you can find different colors, different shapes and configurations of batteries. Photos of different options can be seen below.

Modern heating radiators can have absolutely any color

- Compactness. Obviously, vertical radiators can give you more space at the bottom of the room.

- The range of fastenings is thought out. This is due to the fact that such devices play an important decorative role. Mounting heating radiators to the wall can be chosen in a variety of ways - the manufacturers have taken care of this.

- Easy to install. A user without special skills and knowledge can install vertical radiators. You just need to follow the rules and connection diagram.

- Wall mounting. Very often, radiators under windows need to be eliminated, and vertical radiators are a good option for replacing them.

- Large heat exchange area. Of course, it is very easy to find space on the wall to install large batteries. In addition, options such as radiators in walls have now become common.

There are several disadvantages of vertical-type heating batteries:

- Price. The very first drawback that worries many. After all, such batteries are original, so they are more expensive than regular ones.

- Efficiency. A lot of heat during battery operation will remain under the ceiling and will not participate in convection processes. That is why experts advise placing vertical batteries closer to the floor.

Performance and practicality

Now you know what inverter heaters are. Such heating devices differ from others not only in efficiency, but also in productivity. It is worth noting that an inverter heater is capable of heating a room even at the minimum temperature. At the same time, the efficiency remains quite high. During operation, the equipment shows the ratio of energy expended and the amount of heat generated. This proportion is designated EER. This indicator for inverter heaters is almost equal to 4.

In other words, with a unit consumption of 250 kW, 1 kW of heat is obtained. This indicator is quite good for household appliances.

Inverter heater and home heating with electricity

Inverter heaters, reviews of which are often positive, can be used for heating living spaces. This is especially true if the system is powered from the main power line. This method has already won many fans. Inverter heaters are installed wherever there is access to electricity.

Moreover, such equipment can be used without obtaining permits. This is another plus of the unit. In other words, to install a heating system, there is no need to contact the relevant authorities to obtain permission to install an inverter heater. Another pleasant point for users is the cost of equipment. This figure is significantly lower than the price of other heating systems.

Is it possible to replace a gas boiler?

An inverter heater can replace a conventional gas boiler. In this case, the operating principle of the unit does not change. With an integrated inverter heater, the operating principle of the system will be as follows: electricity will pass through the inverter heater before entering the boiler. This will generate an induction current. If the power is turned off, the boiler will continue to operate, but from the battery. The heater includes a heat exchanger and a magnetic part.

What is an infrared heater?

Recently, infrared inverter heaters have gained particular popularity. Such units are ideal for heating not only residential premises, but also outbuildings, country houses and verandas.

The main feature of an infrared inverter heater is its ability to withstand moisture and natural precipitation. Heating devices of other types are not capable of this.

Operating principle of an inverter air conditioner

In essence, such an air conditioner is an inverter electric heater. The principle of its operation is not so complicated. The operation of an inverter air conditioner resembles the operation of a heat pump. The unit has not only an internal, but also an external unit. At the same time, everyone performs their functions. The indoor unit contains a heat exchanger in which freon condenses under fairly high pressure. During this process, the temperature can reach 80°C.

After heating, the freon flows into the external unit. At the same time, the pressure in the system decreases. As a result of such a difference, freon passes from a liquid state to a gaseous state. Thanks to this feature, an inverter air conditioner can take warm air from the street, even at sub-zero temperatures.

It is worth noting that such equipment is ideal as additional heating for offices and private houses, cottages, and garages.

An inverter for a boiler allows you to prevent downtime of the entire system in situations such as power outages or failures. Long-term inoperability of heating equipment during the cold season is usually the main reason for unscheduled repairs of the entire system. An inverter for a heating boiler acts as a means of protection against such troubles.

Scope and purpose

The equipment used to heat water and distill it through a pipeline is energy-dependent, that is, the efficiency of operation is directly determined by the quality of the voltage of the electrical networks. In such conditions, it is recommended to use an inverter for the heating boiler. As a result, in case of any unforeseen situation, be it a power outage, power surges or an accident, the equipment will be protected from breakdown.

Watch the video, the scope of application of the device:

As a consequence of such a situation, the entire system may fail if, due to a power outage, there is a long-term downtime of equipment during the winter months. An electric inverter for a heating boiler is used to protect any type of device: gas, liquid and solid fuel.

Classification of devices

This type of equipment performs the function of a battery that maintains the energy supply of boiler equipment for a period of time from several hours to several days. The following types of backup power supplies are distinguished:

- “Off-line” - devices of this kind, with acceptable values of the parameters of the electrical network, usually “sleep”, that is, they do not participate in the operation of the heating equipment, since the parameters of the electrical network are stable. If there are quite large deviations (jumps and fluctuations) or in the case when electric inverter heating boilers are completely disconnected from the network, then the UPS, also known as an uninterruptible power supply, immediately switches to backup power to the equipment.

- “Line-interactive” is a universal option that combines an “off-line” source and voltage stabilizer. As a result, boiler equipment, with acceptable values of electrical parameters, is powered from the network, and the output voltage is controlled by a stabilizer and additional filters, whose task is to smooth out noise and interference from the network to which the inverter heating boiler is connected.

- “On-line” - a device of this type is in operation constantly, the rough diagram of connecting the boiler will have the following form: electrical network - UPS - inverter boiler for heating.

The operating principle of the latter option is based on repeated conversion of the power grid parameters. First, the alternating voltage at the inverter input is converted into a constant equivalent with a value of 12 V, then the reverse action occurs, as a result of which the voltage at the output of the inverter apparatus becomes alternating with a value of 220 V. A huge advantage of such a device is that the inverter boiler of the heating system is powered by high quality voltage. But there is also a minus - the significant cost of the UPS and the low level of performance.

Let's watch the video, the operation of various types of backup power supplies:

Also, backup inverter power supply sources are divided into types:

- Devices without batteries – in this case, it is possible to connect batteries;

- Devices with built-in batteries; in this design, capacity expansion through external batteries is excluded, and the inverter boiler of the heating system operates in autonomous mode for no more than 10 minutes;

- A universal option – with the ability to expand capacity and with a built-in battery.

Each of the options assumes a certain operating life of the heating equipment with a connected UPS. The best option is the ability to connect external batteries, which increases the operating time of the uninterruptible power supply.

How to choose an inverter device

First of all, it is necessary to determine whether the inverter for a gas or solid fuel boiler is compatible with the selected type of power source. Some versions of boiler equipment conflict when connecting a device with a “line-interactive” operating mechanism, due to the lack of a pass-through neutral. The most popular option is “on-line”, which can be explained quite simply: the boiler is provided with high quality voltage.

Watch the video, selection criteria:

Additionally, the power of the heating equipment is taken into account, which must correspond to the capacity of the UPS battery. This will ensure sufficient battery life for the equipment.

By the way, the duration of operation of the backup power supply is also important, which should be taken into account when purchasing, especially if the task is to select an inverter for a gas or solid fuel boiler that can maintain the operation of the heating device for several days.

Review of characteristics of popular models

CyberPower CPS 600 E

As an example of an “on-line” system, we can consider the Victron PracticVolt-0212-1/100 device. Its advantage is that there is no delay when switching to backup power supply. In addition, this option can provide up to 7 hours of autonomous power supply to the heating device. The package includes a maintenance-free battery with a capacity of 100 Ah, a charger and the inverter itself for the gas boiler. The price of the entire set of equipment is 36,000 rubles.

Another option is the CyberPower CPS 600 E model. Its price is only 11,500 rubles, but in terms of technical characteristics this version is in no way inferior. The inverter converts DC voltage into AC equivalent and is suitable for a 600 VA load. Input voltage range: from 170 to 270 V. It is possible to increase the device capacity. The kit includes a 100 Ah battery. Another solution of the same brand is CSP 1000 E. This device powers an inverter heating boiler for 14 hours, its price is about 22,000 rubles.

Installation Features

The main problem of UPS is the reduction in their service life when the device is exposed to high temperatures for a long time. It is recommended to maintain the temperature within 20-25 degrees. The main mistake users make is installing uninterruptible power supplies in close proximity to heating equipment.

Watch the video to see the correct connection to the boiler:

When connecting the inverter to the boiler, you should be especially careful to observe the polarity and ensure that the equipment is grounded. If you make a mistake when connecting the phase and neutral, then the electrical part of the equipment will have operational problems. To make sure that the phase connection is correct, you should first start the UPS without connecting it to the network, after which the phase is determined using a special tool and you can turn on the device to the mains.

If the predetermined phase still remains on the same contact, then the steps to connect the inverter have been carried out correctly. It is also advisable to use a minimum length of wires between the UPS and boiler equipment.

Thus, the benefits of an autonomous power source are quite great, which is especially noticeable when it comes to highly sensitive equipment, such as gas heating equipment. The inverter is selected in accordance with the power of the heating device. The type of UPS itself is also taken into account: with a built-in battery or with an external battery. Each option has its pros and cons, which will ultimately affect the duration of offline operation and the quality of the voltage supplied to the input of the boiler equipment.

Not long ago, an inverter heater appeared on the heating systems market. This invention quickly became popular due to its high performance and cost-effectiveness. This is a new generation of equipment, created on the basis of the latest advances in the study of electric current signals. The main advantages of the system are the least noise and the minimum range of temperature fluctuations during prolonged heating.

Economical and powerful heater

Main characteristics

The latest inverter heaters operate in automatic mode. When the device reaches the set temperature mark, the system does not turn off, but switches to a reduced power level. Due to this scheme, the room will always have the required level of heat. The equipment is economical and consumes minimal energy, since there is no need to constantly turn the heater on and off.

Based on the principle of operation, an inverter heater for a home is similar to an air conditioner. Its main part is a heat pump with external and internal units. One of them contains a heat exchanger, inside of which freon is formed. Its temperature can rise to 80 degrees, after which it moves to an external unit with a lower pressure. After this, freon is converted from a liquid form to a gaseous state. As a result of this transformation, a large amount of thermal energy is produced.

In this video you will learn how to choose an inverter:

Thanks to this operating principle, the inverter heater is very efficient. It is able to create a comfortable temperature even in a very cold space.

Advantages and disadvantages

A modern electric inverter heater is the optimal solution for the home. The equipment has many advantages:

- Economical. The unit requires a small amount of current to operate. Due to the absence of the need to restart, the device operates for a long time. Compared to other devices, energy savings are 40%.

- Performance and practicality. The device warms even at extremely low temperatures without loss of efficiency.

- Environmental friendliness and safety.

- Almost silent operation. This criterion is achieved by reducing the rotation speed at partial load.

However, each equipment has its drawbacks. This heater was no exception. The inverter has the following disadvantages:

- High price compared to other types of heating systems.

- Sensitivity to sudden changes in voltage.

- Difficulty in selecting spare parts. The parts are not standard, so it may take several weeks for the equipment to be repaired by the service center.

Application in heating systems

The inverter device is successfully used in electric heating systems. The invention has a lot of positive reviews. It can be used in any place where there is access to electricity. This equipment can be used without special permission to install a heating system.

Such an inverter can easily replace a gas boiler

Such an inverter can easily replace a gas boiler The unit can replace a traditional gas boiler. In this case, the heating system with a built-in inverter device will work as follows:

- Passing through the system, electricity will enter the boiler.

- The inverter boiler will produce an induction current.

- When the power is turned off, the equipment will continue to work thanks to the battery.

- The heater consists of a heat exchanger and a magnetic part.

Types of devices

There are two types of inverter heaters - infrared and gas. The first type is used for heating residential and utility rooms, as well as cottages and verandas. Such equipment tolerates moisture and precipitation well.

The gas heater runs on natural and liquefied fuel. Its main advantage is its ability to maintain heat over large areas. This is a very productive device, operating with low fuel consumption. It is very easy to use and mobile.

In addition, there are inverter air conditioners. Heat pumps are incorporated into the mechanism of these devices.

Inverters differ, at a minimum, in heating power

Inverters differ, at a minimum, in heating power New generation air conditioners

Usually this equipment is associated only with cooling the air in the apartment. But it is not so. Inverter air conditioners can not only cool, but also warm the living space.

Such air conditioners are used in apartments and offices. But if the temperature in the winter is -26 degrees, the device will not be able to cope with heating the room alone. This option will be inconvenient for use in a country house or garage. The air conditioner is environmentally friendly. During its operation, no fuel is burned, therefore there are no emissions of harmful substances into the atmosphere.

Inverter air conditioners have many advantages . The following advantages of the systems are highlighted:

- Adjustment of the desired temperature occurs quickly.

- The device operates almost silently. This is achieved through built-in fans operating at low speed.

- Compared to other models, an inverter air conditioner saves up to 65% of electricity.

- When using the system, the occurrence of drafts is excluded, since there are no sudden temperature changes.

However, each mechanism has its drawbacks. An inverter air conditioner has the following disadvantages:

- Higher price compared to other types of systems.

- Sensitive electronics that respond to voltage fluctuations.

- Inability to turn on the compressor at temperatures of -10 and +42 degrees.

- Difficulty in selecting spare parts.

Equipment Manufacturers

The leader in the production of inverter air conditioners is Japan. It was in this country that such systems were first developed. Daikin produces wall-mounted equipment for residential maintenance. Air conditioners have minimal noise levels and also purify the air. Some models are equipped with a special energy saving sensor. If there is no one in the room for more than 20 minutes, the system switches to this mode.